TEMPERATURE CONTROL

Electric motors, installed in our mixers, as standard are featured with double insulation layer of F class (temperature resistance for insulation of F class is equal to 155°C).

The system for monitoring motor’s wirings temperature consists of three bimetal thermo-contacts located at each of motor phases. If the temperature limit is exceeded, thermo-contacts gets open, this signal is immediately received by electronic module. Relevant alarm is reported, mixer is shut down instantly.

Optionally, mixer can be equipped with additional temperature probe Pt100 located at one of stator’s phases, purposed for reading of current value of motor’s wirings temperature.

In case of special requirements there is possibility to install additional PTC sensors at each of motor phases. These sensors provide the same functionality as thermo-contacts.

Control circuits for temperature monitoring are build-in the same electronic modules as control circuits for leakage monitoring.

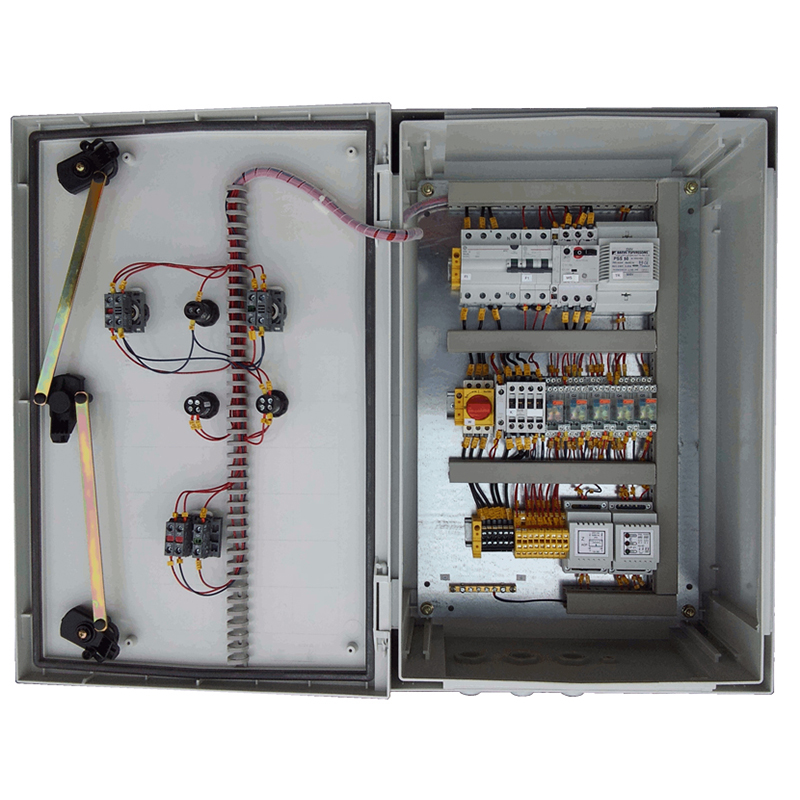

CONTROL CABINET

Full-scale control cabinet, water tightness of IP54 class. Purposed for installation on site in close distance from mixer.

Notice: in case any other control systems are required, please contact our engineer.

There are no reviews yet.